The skin packing machine is a new packing technology in the global market and has become one of the main measures in product package. They are widely used for packing hardware, instruments, stationery, toys, table wares, crafts, souvenirs, medical device, electrical components, etc with very low cost and advantages of transparent and beautiful, strong sense of three dimension, damp-proof, dust-proof and anti-spare parts.

The skin packing machine has stable performance, so it is easy to operate and the packing process is simple. We also provide the skin packing film, color cardboard, design and produce special model machine for customers.

II Technical Parameter

| Model | TB390 | |

| Voltage | 380V/3PH, 50-60HZ | 220V/1PH, 50-60HZ |

| Packing area | 390×540 mm | |

| Packing speed | 30-60 times/hour | |

| Width of packing film | 450 mm | |

| Packing material | PVC, PE, PP skin packing film | |

| Power of heating pips | 9 Kw | |

| Motor power of pump | 0.75 Kw | 0.90 Kw |

| Total power of machine | 10 Kw | 10 Kw |

| Machine size (with worktable) | 1515×605×1355 mm | |

| Dimension after packing | 970×660×1410mm | |

| Weight | 160Kg | |

Skin packaging machine is a new packing technology, and it has become one of main packing method in the international market for exported commodity. It is widely used in hardware & tools, toy, stationery, small daily use articles, battery, handicraft, auto parts & accessories, electrical appliance parts, souvenir, etc. After packing, it has features of transparent, artistic, moisture-proof, dustproof, guarding against disperses. No mould is needed for any shape objects packing. Furthermore, it enables packing objects more attractive with color printed card.

The operation process of TB390 Skin packaging

machine is simple and with stable & reliable performance. For the

convenience to clients, our company is able to supply skin packing film,

and color printed card. We also customize machine according to

customer’s special requirement.

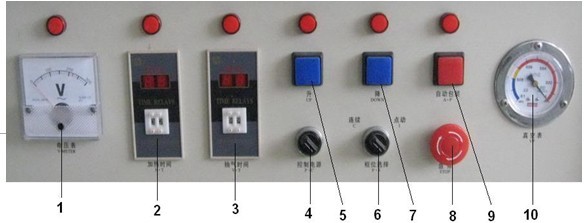

III. OPERATION PANEL

1.Control Panel Diagram:

1.Voltage meter (V) 2. Heating time (JS3) 3. Vacuum time (JS5)

4. Power switch (K2) 5. Ascension (K4) 6. Frame position (K3)

7. Descension (K5) 8. Urgent stop (K9) 9. Automatic pack(K6)

10. Vacuum gauge (Z)

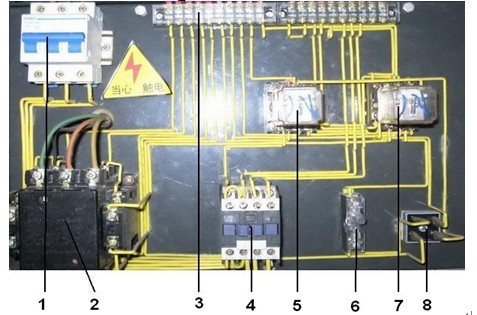

2.Circuit board diagram:

1.Main switch (K1) 2.AC contactor for heater (CJ1)

3.Wire joint board (TB) 4.AC contactor for vacuum pump (CJ2)

5.Middle relay (J3) 6.Fuse of ascension (FU)

7.Middle relay (J4) 8.Bridge type rectifier (Q)